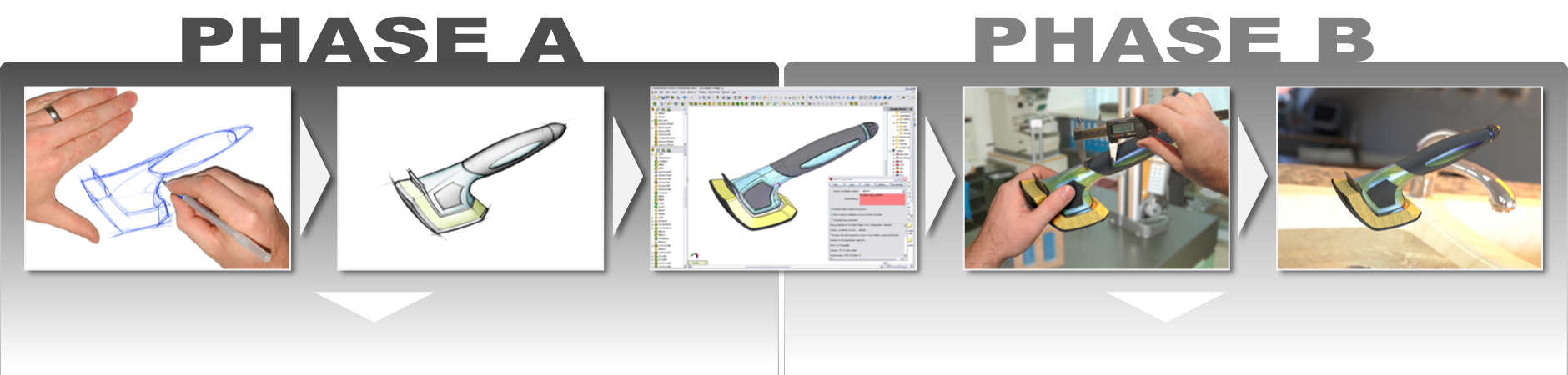

The ‘Fast-Track’ Invention & Prototype Life-cycle

For folks who are unfamiliar with the production world, knowing where to begin following that ‘Eureka-moment’ can be daunting. Luckily, that’s where we can help! Many start-ups and inventors would prefer to trim the development cycle to its bare essentials in order to reduce time and costs. The workflow outlined below strips the design process down to it’s mission-critical milestones. The Fast-Track process still allows us to deliver a polished final product, but within a much tighter budget.

Development-Process Guidance

Every product is different, and the best plan of attack will always vary from client to client. Once you’ve brought us up-to-speed on your new product; we’ll help you find the most cost effective approach of developing the design; and guide you through any hurdles you may encounter along the way.

Design Optimization and Refinement

Developing a profitable product is contingent on minimizing your investment dollars, part costs, and return rates. In addition to optimizing the aesthetics and ergonomics, our industrial design phase will help find ways to balance long-term reliability with the most cost-effective production and assembly strategy.

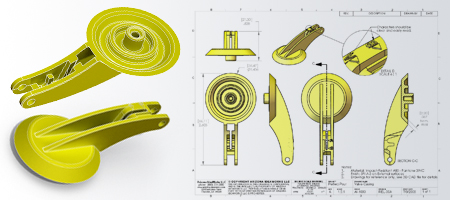

Parametric CAD Solid Modeling

Using advanced CAD software, we’ll construct your “virtual” product in a 3D environment. This allows us to optimize the design using mechanical simulations, moldability analysis, and even calculate high-load stress failures well ahead of tooling or production.

Visualization for Investors / Marketing

When it comes to selling an idea, a little-eye candy goes a LONG way. Using the actual CAD data (or CAD mock-ups known as “CG stage props”), we can deliver photo-realistic renderings and animations that tell the product’s story. This approach helps fuel investment campaigns, launch advertising, and even create a strong web-presence long before tooling has even begun.

Collaborate with Rapid Prototype Suppliers

Building a rapid prototype (“RP”) to test your final CAD design is the most reliable way to test a design prior to heading off to tooling. In fact, most modern prototype facilities REQUIRE a CAD before they can program their machinery to build your parts. We frequently connect our clients to our favorite RP partners and spend a little extra time to make sure each party has everything they need in order to move forward.

Compare and select Ideal Materials and Processes

SLA, SLS, FDM, LOM, Rapid CNC, MakerBot, Silicon & Urethane Casting, (etc)… When it comes to prototyping technologies, the available options are almost limitless. However, we’ve worked with each of the technologies for many years and understand their pro’s and con’s based on any given set of requirements. Therefore helping you select the right technology for your project is very much a natural part of our workflow.

Assemble Prototype, Review for Fit and Finish

Once the RP parts are ready, we review them for fit, finish, and performance. Granted, prototype materials typically pale in comparison to the toughness of production plastics, but they serve their purpose extreme well for qualifying the general design features and overall appearance. In this stage we also source any off-shelf hardware to assure everything assembles as intended in the driving CAD documents.

Refine CAD to Maximize Performance

Once we’ve exhaustively reviewed the RP parts and assembly for fit, finish, and performance; we then outline a “punch-list” for any final refinements or performance tweaks that can be applied; then apply them to the CAD assembly before releasing the “Initial Release” Production Package for final tooling and fabrication.