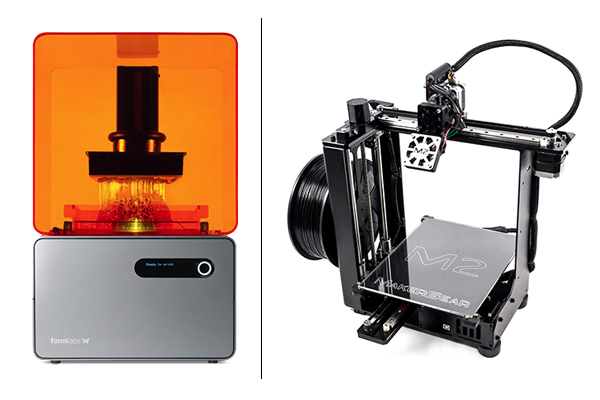

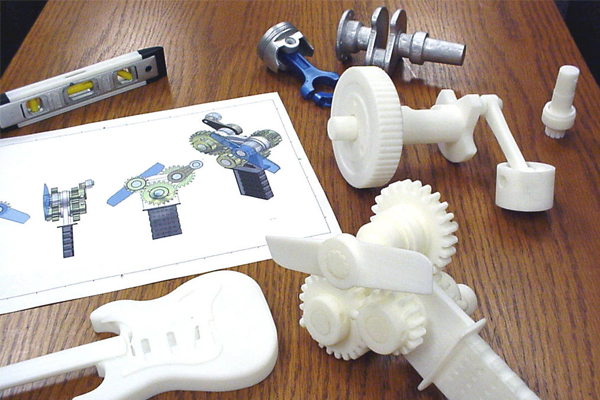

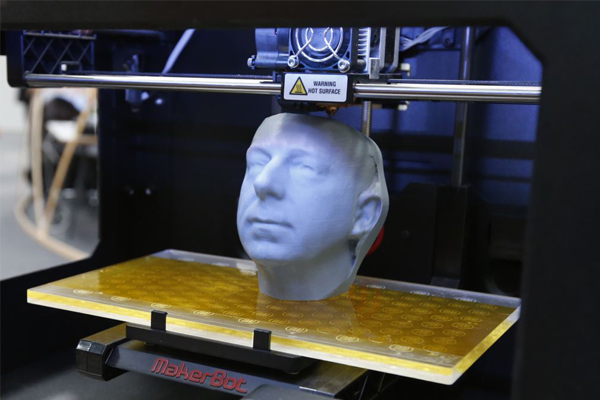

Over the years, 3D printing has known many names and technologies. When I started designing consumer products in 1998, it was standard practice to send our finished CAD files out to service bureaus like PADT Inc so that we could double-checking our parts for fit and function prior to releasing them to the molders. Back then, the machines were extremely expensive, slow, somewhat inaccurate (by today’s standards at least) and the resulting parts were often extremely brittle. But since then, entry-level machines have gotten smaller, cheaper, and faster; high-end equipment has evolved to being able to supply large, extremely intricate parts that can rival (but not yet match) production grade plastics in terms of finish and durability. Machines that once only fit in the Niche’ market of big-budgeted design studios have now become accessible enough that small businesses and even home-hobbyists can own them. I wouldn’t go so far as to 3D printers are “plug-and-play” just yet; operators still need to understand the inner workings of the equipment and technology (including bed and nozzle temperatures, prints speeds and resin cooling rates) but with a growing community of users; support is usually pretty easy to find. If there is one point that we can count on, its that adoption by the masses is an accelerator for refinement and competition; It wont be long before 3D printers are commonplace in big-box retailers and craft-outlets alike!

Contact Info

Phone: (480) 231-2886